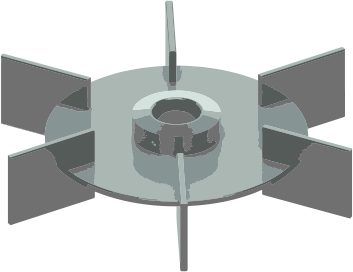

Rushton Turbine Impeller Manufacturer

R2 Quality Castings has over 40 years of experience manufacturing top-quality rushton turbine impellers for mixing applications requiring robust radial flow patterns. We engineer impellers to optimize shear rates and pumping performance for your specific process parameters. Trust R2 Quality Castings for all your rushton turbine impeller needs, from pharmaceutical to industrial mixing applications.

Rushton Turbine Impeller Uses

Rushton turbine impellers are often chosen for applications requiring elongated tanks or low-level mixing. Because of their vertical angle of attack, radial impellers such as rushton turbines generate high-shear rates and exhibit a relatively low pumping number, making them particularly sensitive to changes in viscosity. The reactivity to viscosity changes makes rushton impellers ideal for processes where maintaining precise control over fluid properties and achieving consistent results are vital, such as applications in the pharmaceutical industry.

Radial Flow Impellers for Liquid-Gas Mixing

Rushton impellers play a significant role in liquid-gas mixing because of their radial flow pattern generation. The pattern creates separate circulation currents above and below each impeller, providing little interaction between fluid streams from different impellers. The segregation forms a barrier to axial flow and top-to-bottom mixing throughout the tank. This is more effective for liquid-gas mixing than an axial mixing impeller, as axial flow impellers do not promote consistent dispersion of gas within liquids and can create localized pockets of gas or liquids within the tank. The radial flow patterns offered by rushton turbine impellers lead to improved gas-liquid contact and enhanced mass transfer within the tank, making them the ideal choice for liquid-gas mixing applications.

Trusted Manufacturer of Rushton Turbine Impellers

Rushton turbine impellers are utilized in a variety of industries that require effective and consistent chemical mixing. Their design facilitates the optimal dispersion of liquids and solids in fluid systems, promoting efficient chemical reactions and preventing the settling of particles or pockets of unmixed materials.

R2 Quality Castings specializes in crafting custom Rushton turbine impellers tailored to meet the specific demands of any industry. Our precision casting foundry meticulously attends to each component's intricacies, guaranteeing your product meets the highest quality standards. We subject every impeller to a rigorous quality-verification testing process, showcasing our commitment to excellence.

Our dedication to delivering top-notch quality extends to every aspect - it’s a fundamental principle with an unwavering commitment. See more of our investment casting capabilities including for propellers.