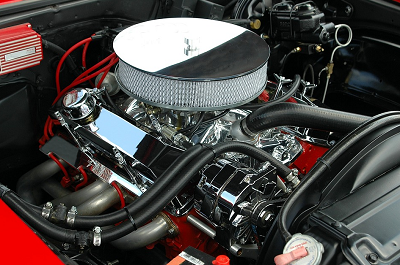

Investment Casting for the Automotive Parts Industry

Precision Components for OEM and Aftermarket

The automotive industry requires complex, durable and lightweight parts to improve performance and efficiency. We specialize in manufacturing these components using precision investment casting. While other methods like sand casting or die casting are used for simpler, high-volume parts, investment casting is the ideal solution for complex geometries, tight tolerances and high-performance alloys.

R2 Quality Castings produces custom vehicle parts for a wide range of applications. We deliver fast lead times, competitive pricing, and unmatched quality. Contact us today to get a quote.

Why Investment Casting for Automotive Parts?

Precision investment casting (also known as the "lost wax" process) is essential for modern automotive manufacturing. We find it delivers critical advantages over other production methods for high-performance and critical components.

- Complex Geometries: Our process creates intricate parts like transmission forks, rocker arms, and cylinder heads as a single, net-shape piece. This reduces assembly points and machining time.

- Superior Materials: We pour a wide range of high-performance ferrous and non-ferrous alloys that other casting methods cannot handle, including stainless steel, ductile iron, and carbon steels.

- Weight Reduction: Investment casting allows for thin-walled, lightweight designs without sacrificing strength, which is critical for improving fuel efficiency.

- Close Tolerances: Our ISO 9001:2015 certified foundry produces parts with high dimensional accuracy. We consistently hold tolerances of +/- .010” for the first inch and add +/- .003” for each additional inch.

Automotive Components We Cast

We manufacture critical components for nearly every system in a vehicle. Our parts are used by OEMs and aftermarket suppliers for their strength and reliability.

We manufacture critical components for nearly every system in a vehicle. Our parts are used by OEMs and aftermarket suppliers for their strength and reliability.

Powertrain and Engine Parts

- Camshafts

- Rocker arms

- Cylinder heads

- Transmission shift forks

- Driveshaft components

Chassis and Suspension Parts

- Suspension brackets and mounts

- Steering knuckles

- Brake components

Body and Interior Components

- Hood and trunk hinge components

- Door and side panel structural parts

Materials for Automotive Castings

The material choice is critical for performance. We pour a wide selection of ferrous and non-ferrous alloys to meet your specific requirements for strength, weight, heat, and corrosion resistance.

Material Options for Automotive Parts

- Stainless Steel (For exhaust and high-heat parts)

- Carbon Steel (For high-strength brackets and gears)

- Ductile Iron (For suspension and chassis parts)

- Aluminum (For lightweight components)

- Brass

- Bronze

- Copper

Your Partner for Automotive Castings

Businesses across the automotive industry rely on R2 Quality Castings. Our rigorous quality assurance and product testing services ensure that every intricate component meets the highest standards before it leaves our foundry. We provide the high-quality, reliable cast products you need, manufactured at our Waukesha, Wisconsin facility.